Supposed you’re a paint manufacturer fabricating hundreds of different recipes. For the past ten months in a row, the specification limits for several products have not been met. Worried about this reoccurrence and the severity of the impact, a product manager may demand changes to the recipe, the process or even put production on hold to calibrate equipment. However, by acting every time a specification is not met and trying to find solutions without having a clear direction, doesn’t guarantee a stable and more predictable process.

The moral of the story – you cannot eliminate risk completely. No matter the industry or the products manufactured, you want to get to a situation where you know what can go wrong, how this will impact your operation, continuity, finance, etc. And, based on that evaluation, you can decide whether you need to take countermeasures. Failure Modes and Effects Analysis (FMEA) or risk-based quality management can help exactly with that.

FMEA: what, when and why?

Failure Modes and Effects Analysis (FMEA) is a systematic approach that helps uncover the possibilities in which a product or a process can fail. The proactive method identifies risks, assesses their impact, and the ways in which these lead to waste and other unpredictable outcomes.

If done properly, the analysis can highlight parts of the process that are most in need of change. And, because it helps with early detection of variability problems, an FMEA enhances control, minimizing the defect rate, improving the chances of a First Time Right.

Since manufacturers are striving for consistent quality and reliable processes, it’s advisable to perform occasional FMEAs throughout the lifetime of a process. Other times when the risk-based analysis may come in handy:

- To address and improve a failed process

- When considering changes to an existent process

- If you want to monitor specific quality improvement goals

- With new products, processes, or services

There are two types of FMEAs, Design FMEA and Process FMEA. The previous looks at the way in which a system, product, or service was designed and is beneficial especially when testing out new products. The latter addresses potential failures in ongoing processes and procedures as well as the impact of these on operations.

Improvement based on risk priority

For both types of FMEA, the risks and their resulting effects are registered in an FMEA form. This records the severity (how bad is the outcome), the frequency (how often will this happen) and the detectability (how likely are you to detect this problem before it becomes one you cannot afford).

All these criteria allow manufacturers to quantify risk and objectively assign a Risk Priority Number (or RPN). The RPN aids understanding and consequently helps teams to take action in order to eliminate and reduce risk in their operations.

Risk assessment: Excel vs. software

While helpful, many manufacturers steer away from filling out FMEAs since this can be very time-consuming and sluggish. And, as you probably guessed, Excel is the most used tool for FMEA and risk assessment. If you’re new to FMEA, Excel might be enough to familiarize yourself with this type of analysis.

But if you want to apply FMEA at scale, it’s best to deploy sophisticated software. That will be the only way to keep the analysis manageable, given the huge number of products, processes, and all their potential failure modes.

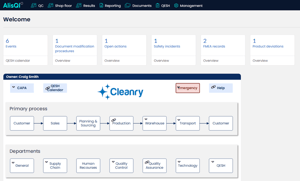

How to do it fast and help your business? Our QMS software, AlisQI allows you to gather and analyze risk data from the production floor to maintenance teams and everyone closely involved in the process. The smart system enables teams to gain visibility and easily assign priority, computing the RPN with the expression engine. It doesn’t end with the RPN. To ensure improvement, we connect this to the CAPA list to keep track of the countermeasures. We also assign owners and use workflows for process management. This way, you’ll eliminate and counter the risk you cannot afford and focus on what truly matters.