The only way to control the quality of a product is to test it. Not once, or for one aspect of the product, but regularly and for everything that determines the quality of raw material or a finished good. That’s a lot of testing.

Quality is not an absolute but rather a continuum or aspiration described by predefined specifications against which it is measured. These specs are part of a contract you have made with your customers – or with yourself – to deliver on quality.

Testing is a repetitive task, and you can’t fall asleep on the job because this could have catastrophic consequences. Just as the automation of manufacturing processes has led to fewer non-conformities (and so better end products), the automation of Quality Management workflows leads to drastically fewer recalls, complaints, or even claims because overall quality has improved.

Yet many manufacturers still evaluate manually or with complex spreadsheets in Excel. How do such approaches compare with what automation looks like in our Quality Management solution, AlisQI?

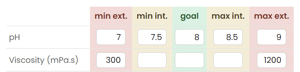

For starters, the graphic below shows AlisQI’s “traffic light” alert system for the pH specification of a chemical product. For numeric fields, AlisQI operates with five limit values: two external limit values, two internal limit values, and a target value, the quality aspiration.

The two external limits (red) are used to indicate absolute limits. If these limits are breached the result value is off-spec. In case of an off-spec, an alarm is generated automatically. The two internal limits (orange) indicate that the absolute limits are in danger of being breached. The purpose of these limits is to warn the user that a measurement is drifting outside a safe range.

This seems simple enough. However, without AlisQI, how would you share these results and make them instantly comprehensible to everyone on the factory floor or in the boardroom? Excel spreadsheets look chaotic and off-putting to almost anyone but the person who created them, so what happens if he or she is away or leaves the company?

The crucial aspect of all this is the automatic generation of an alarm. Anyone spotting a non-conformity in Excel still has to make the decision to pick up the phone, write an email or shout across the factory floor that something has gone wrong. Automation means that both the test observations and the actions they trigger are part of a system, accessible to all who need to see it and help resolve the problem.

More about alarms later.

Let’s look at a more complicated graphic, a time series of final product inspections.

Each set of specifications (called a ‘specification version’ in AlisQI) has a start date. All result values are always checked against the specification version that was valid at the time of the measurement. In a control chart, you can see this for numerical values as follows:

In this example, the specifications were adjusted upwards because the quality measurements were outside the set specifications. We can clearly see that, until 2018-05-30, this product was tested against the specification values applicable at that time.

Assuming that the Excel-approach would have been alert enough to act on the changes in quality measurements, graphs such as these can be generated in spreadsheets. But again, they would probably be ‘owned’ by just one or a handful of colleagues, limiting its usefulness. In AlisQI, all data are part of an intelligent system that is making inferences all the time about how quality is performing throughout your production processes.

Sound the alarm!

Alarms, again, are a case in point. In AlisQI, when a result has been entered which is outside of the external specifications, an Off Spec alarm triggers a cascade of actions. A second type of alert, the Out of Control alarm, flags up patterns where test observations are drifting from the target specification (i.e., they are clustering inside either of the two external limits, the orange segments of the AlisQI control panel).

Manual or Excel Quality Management relies on people to observe these patterns, and then act on them. AlisQI not only spots patterns that are invisible to the human eye, but it also formalizes workflows and protocols to turn insight into action.

Our final diagram shows all alarms (active and inactive) for a particular analysis set. Clicking on the bell icon highlights results which were off-spec:

You may be able to compile a report like this manually or through Excel but you’ll spend all day doing it, and the inevitable errors will skew your insight. Not that you’ll have the time to spot or correct any errors, let alone analyze what these data mean…

What AlisQI does is give you back meaningful time where you can make decisions that will transform Quality Management within your business. If you could spare us a few hours of that time now, we could set up a specification ‘trajectory’ for you as part of a demo or pilot. Seeing is believing.

Have you quantified how much time you spend going through lists of measurement data by hand, or plotting it in complicated spreadsheets? Did any off-spec observations recently slip through the net because they weren’t spotted, or because you weren’t notified of them? And how much hassle, rework, claim costs and problem-solving were you landed with as a result?

Many leading manufacturers across a wide range of industries depend on AlisQI to guard and guarantee the quality of what they make. Off-specs won’t catch them off guard again.

Five SPC mistakes that you do not need to make...

Others did that for you…